|

Image

|

|

Image

|

|

Image

|

About ten years ago my wife asked a question I'll always remember. She asked if I could have anything I wanted (within the bounds of reality) what would it be. After careful consideration, I answered, "My own private pond stocked with monster bass."

We lived in the city at the time, but both of us had a strong desire to live in the country. There's just something special about rural living.

We are located in California's central San Joaquin Valley. After five years in that small house in the city we finally got tired of neighbors and sold our home. We moved in with my parents for a short time while looking for a place in the country. I still had that dream in the back of my mind and every place we saw I sized up with the possibility of building a pond.

When I saw the place God would have us live it was clear that a pond was a distinct possibility. We landed on seven acres on the east side of the valley close to the foothills with a beautiful view of the Sierra Nevada Mountains.

We were blessed to have bought this place before the big swell in real estate values. When the housing market doubled from when we bought, the funding existed to begin construction.

I am still amazed my wife had confidence in me to take on such a large project. She knew I had studied pond construction at length, reading anything I could get my hands on. This included The United States Department of Agriculture handbook 590, called "Ponds-Planning, Design and Construction." I also did a lot of research online where I found the most helpful web site and publication of all, Pond Boss. I instantly subscribed to Pond Boss and I have archived every single issue in the order they were sent so I can go back to relevant articles when necessary.

I broke ground in June of 2005 with a distinct budget in mind. I hired long time friend Doug Tienken of Tienken Heavy Equipment to do the digging because I knew he would let me have constant supervision and input and he was willing to work on my days off letting me drive the water truck to save money. They had never built and sculpted a pond like the one I had designed, but they were experienced in irrigation holding ponds and understood the importance of keyways and levy compaction.

The dirt I have to work with is rich in adobe clay so I decided not to use a liner. With the project underway the first problem we ran into was hot, dry summer days sucking moisture out of the dirt quickly. With adobe clay, moisture levels for compaction parallel potters clay on a wheel. It almost needs to be sticky nasty mud. It clings to everything. Once we figured out how to mix water and dirt, filling of the keyway went much faster.

The job took longer than we thought for several reasons. In this area we have a crusty, rocky soils called "hardpan." This is a layer of rock-like substance that can be anywhere from 18" to 48" deep and approximately 12" to 18" thick. It is so hard that ripper teeth on the bull dozer wear out quickly and leave white smoke in the wake of the ripper. After about a month and a half of working four days a week we finally had a rough hole about five thousand dollars over budget. The surface area of the pond worked out just larger than an acre and a half with a 30 x 90 foot island.

Next we tackled habitat, structure and spawning beds. A large beach area for swimming and wading was also in the plans. The contractor graciously contributed some 8" PVC pipe and several rolls of used irrigation hose. I came up with the idea for an artificial tree that would not deteriorate like Christmas trees and would be virtually snag proof. We drilled holes in the pipe slightly smaller than the outside diameter of the hose. I forced the hose into the holes. Voila'... limbs like a tree. I also drilled a hole about ten inches from the bottom and ran a piece of 1" PVC through it. That left about two inches sticking out on each side. When placed in the ground the smaller PVC would act like a lock to prevent the pipe from being pulled out of the ground. I took my tractor and post hole auger and drilled holes about 16" to 18" deep. I placed the "trees" in the holes and backfilled, compacting the moist clay as best I could. Then, I tamped several shovels of dirt inside the pipe to make the trees solid.

While I was building trees my friend Doug Tienken was busy bulldozing trees in old, worn out orange groves. He saved all of the old standpipes from row irrigation days. The stand pipes are concrete cylinders that stick up out of the ground at the end of each row of trees. Normally, Doug would just crush them with the tracks of his bulldozer, but I had asked him to keep an eye out for any broken concrete he could find, and to let me know and I would collect it for pond bottom habitat. I ended up receiving about 150 of these stand pipes and breaking them with a sledge hammer into a sort of half shell. When stacked on top of each other in piles they made a great reef-like structure in between the artificial trees.

For the spawning bed I purchased six dump truck loads of 1/4" crushed rock and spread it in the three foot deep area on the back side of the island. Rock was smoothed about 8" thick. In that same area shorter versions of the trees with the limbs closer together were placed to make artificial "bushes" in the spawning area. I made a mound of dirt in the same General area about 15 feet off the bank. That underwater hump Would only be about 16" below the surface so we could plant water lilies after the pond was full.

For the beach we brought in 12 dump truck loads of heavy grit river sand. It was spread so that it made a tidy beach area right behind our house. The beach was designed outward into water about 5 feet deep.

The next big project was irrigation and power around the pond for the aerator and real trees that I had planned for the south side of the pond. I ran almost a half mile of irrigation line and 1200 feet of electrical conduit. I ended up trenching across the pond bottom and up the side of the island, taking water and power for a four plug GFI electrical outlet for the island. I also brought a 2" pipe to the pond for filling and maintaining the water level.

The next project was the aerator system. I purchased a Vertex four diffuser aerator just like the one you see making bubbles in the ad in Pond Boss. During construction of the pond, I had the contractor make a deep channel about 100' long and 24' wide and about 10'h feet deep, the deepest point in the pond. I had them terrace the sides of the channel in 3' lifts to provide bass with ledges. I trenched the pond bottom for the air hose and set a post for the compressor. Before I could install the unit, God blessed us with five days of steady rain, completely filling the deep spot in the pond. My dad and I ended up running nylon rope through the sides of the diffuser unit and dragging it into position in the flooded deep spot. The weighted hose went into the submerged portion of the trench and the rest was buried in the part that wasn't wet. It was a bit of a chore. The bright side is that I was able to test the aerator in the water before filling the pond.

|

Image

The bottom is covered, sunset, all is well. |

|

Image

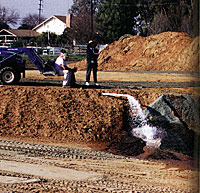

Filling, filling, almost ready ,for fish. |

Next on the agenda was a large slab of concrete and a foundation for the pond house. The bulk of the concrete was for a patio that would butt up against the pond at the water line of the beach with a fire pit formed by the pond house foundation. With that project completed I was ready to turn the well water on. The new gem of a pond took almost ten days to fill, approximately 3,200,000 gallons. Before the water was halfway up I had mallard ducks visiting the pond every morning.

The pond was full in February 2006, and holding water like a moonshine jug, as Mike Otto might say. Canada geese woke us up at 6:00 am ... two weeks after filling the pond. What a blessing.

At the end of March I stocked 7500 fathead minnows and 600 bluegill. 250 northern strain largemouth bass were added at the end of May. The county brought four dozen mosquito minnows for free as part of their mosquito abatement program.

My wife and I went to a local creek and caught about 100 crawdads and just about every time we went, one of us got soaked. She is an amazing, thoughtful woman. During a good stretch of rain bullfrogs showed up on their own. This was another surprise of Nature because the nearest water that could support bullfrogs is about a mile away. I guess they heard of the new habitat and hopped on over.

By November, we figured the bluegill had spawned three times during summer and fall. The original 1 to 2" bluegill were as big as my hand. Their first spawn were 2 to 3" long by November. The second spawn class was 1 to 2 inches. And, we saw tiny, little bitty babies late October. The 3 to 4" bass ranged from 9 to 12 inches, with the largest weighing 14 ounces to a pound. The mosquito fish spawn constantly. Everywhere you look along the edge there are all sizes of mosquito fish, and no mosquito larvae. The bullfrogs have done well too, there are baby bullfrogs every where.

This pond has been such a blessing for our family. My nieces and nephews spent two weeks with us this summer, swimming every day. Four weeks ago my wife and I adopted a baby girl and I can only dream of the adventures she will have growing up with a pond for a back yard.

My sincere thanks go out to Bob Lusk and Pond Boss staff. Mr. Lusk has been there for me all the way, answering questions and providing information that is priceless. Ponds are not as common here in California as they are in Texas, so resources are limited. The amount and quality of information that Mr. Lusk has provided me with is simply amazing. Thank you so much for your help. Most of all I thank God for my health and for allowing us the resources to make this dream come true.

Reprinted with permission from Pond Boss Magazine