Why would anyone go through the trouble of making his or her own tackle? Is it because the overall cost is drastically lower? Or maybe because you have the option of changing subtle details that can make the fish go wild?

Regardless of why you choose to handcraft your tackle, the benefits of this fine art are beyond compare. From sinkers to spinnerbaits and everything in between, ambitious anglers are putting their minds, experience, and hands to work in an attempt to create the perfect product and save a boatload of money.

For me, the choice to manufacture my tackle came after several weeks of hard fishing. During this period, I used a name-brand jig as my primary bait. The problem with these jigs was that the hooks were inferior to others on the market and would fail very frequently. There were instances where I would get hung up in a brush pile or some fallen timber, and after getting the bait unstuck, the hook would be so weak that it would bend straight on the slightest of hook sets. Even worse, the hook would completely break after catching a limited number of fish. While some may not see this as a serious issue, I view it as more than a bit of inconvenience.

To begin the tackle-making process, it is essential to know exactly what you want to accomplish by producing your tackle. Evaluating all of the pertinent details before you begin the production process can almost entirely alleviate all of the negative issues you were having with your previous product. For example, if you recall, my problems were with poor-quality hooks. Rather than duplicating the problem by using the cheapest hooks, I could locate. The hooks that I prefer to use are Daiichi and XPoint. These are two of the sharpest and most durable hooks on the market. Daiichi even makes different jig hooks in their Bleeding Bait product line. It is important to note that not all molds will accept all hook sizes. (Check your mold specifications to determine which hooks will fit your mold)

Changing the type of hooks you use is just the beginning of the creative world of tackle design. With the proper equipment and creative thinking, you can completely design and manufacture your unique tackle style. Whether you want an odd-shaped sinker or a Flippin' Jig with an eye-catching design, the possibilities are endless. Custom colors are essential to some anglers. Having the option of using just the right color combinations to match the forage in your local fishery can significantly increase the number of fish you catch. For tournament anglers, this can mean a significant increase in winnings.

After I became a little more familiar with the whole process of making my jigs, I started to make them more customized. The jigs I produce have specific color combinations to fit my personal preferences. I combine different color skirt materials and various Powder Coat paint colors for the heads to achieve just the right combination.

Another product that takes the personal design process to a whole new level is blank molds. These molds have not been machined. This gives you the ability to take the mold to a local machine shop and have them machine the cavities to your exact specifications. It would help if you had the proper machinery to mill out the cavities for your designs. This is not something that you should attempt to do if you are not an experienced machine operator. Tight tolerances need to be maintained to achieve optimal alignment for each side of the cavity. Your imagination is the limit when it comes to the designs you can produce using a blank mold. If you can envision the design, there is an excellent chance that a highly-skilled machinist can make your dream bait a reality.

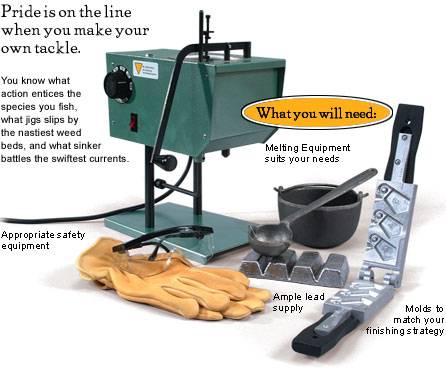

The next and most crucial step is determining the type of tackle molds to use. I went with the most trusted name in tackle molds, Do-It Mold Company, to solve my problems. Do-It offered the most cost-efficient and high-quality molds available. Their catalog also contains many additional items I needed to complete my tasks. I obtained a melting pot, jig skirts, fiber weed guards, powder coat paint, various jig molds, and a great deal of miscellaneous hardware. As with any other project, using the best quality materials will drastically improve the finished product. Nearly every item I received came with directions explaining how to use them properly. After reading the directions, I still wanted to ensure that I was doing everything correctly, so I went to Do-It's website. Once at the site, I had access to a list of various tips and troubleshooting tactics that made the whole process run extremely smoothly.

The lead I used for my initial run of handmade tackle was obtained by melting down a bunch of old sinkers in my basement. Once that supply was depleted, I picked up about 20 pounds of lead wheel weights and other miscellaneous lead items. These various items were then melted down, and the lead was turned into ingots using Do-It's Ingot mold. The nuggets are nice clean lead that can be melted down to produce your custom tackle. Because lead is so readily available, I have yet to purchase any of it. This is another way to keep the cost of tackle at a minimum. Even if you do have to purchase your lead, it is very inexpensive, and you can do so by visiting your local scrapyard. (Caution: Always work with lead in a well-ventilated area)

Establish a well-arranged workplace. Try to place all of your materials to develop a small assembly line. This will reduce the amount of wasted time and materials. Always have a predetermined "cooling area." This is the location where you will place your tackle while the lead is completely cooling down. Before starting your production process, it is a good idea to preheat the mold. This makes the lead flow more fluidly and fills the cavity. Trial and error will help you master the tackle-making craft. I would be lying if I said that I had not messed up less than a couple dozen times. However, it is a straightforward task once you get the rhythm.

When you catch your first fish on a piece of tackle that you have created, pride will fill every inch of your body. Just knowing that you could produce something good enough to entice a big fish to strike makes it well worth the work. Especially when it was your own personally designed, customized tackle that got the job done. The first time I caught something on one of my custom jigs, I was excited. I remember skipping the jig way back underneath a boat dock. After hopping it a few times, a bass just hammered it. Although it wasn't a giant fish, I was elated to catch it on something I made. Since then, I have caught an astounding number of bass on the custom jigs that I created.

As a result of my success with my jigs, I could produce a supplemental income if, of course, I had the time. Several of the anglers that I fish with and against have admired the high quality in my custom tackle. I have had numerous offers to purchase some of my jigs during recent months. Of course, I usually give each person a couple of jigs and then tell them how to make their own. So whether you want to produce high-quality tackle for personal use or start a small tackle-making company, hand-made tackle is the way to go.

For more information about Do-It's various product lines or tips on creating your tackle, visit www.Do-ItMolds.com.